|

Pouch Cell Equipments

|

1] Precision Die Cutter for Pouch Cell Electrode Sheet:

Description:

It is a precision electrode die-cutting machine. It is a must-have tool for

producing specific shapes of positive and negative electrodes with current collectors in

pouch cell production lines. An IR sensor (safety curtain) built into the front of the machine

ensures safe handling when the electrode pads are fed from the front.

It is a necessary tool in the production line of Li-ion pouch cell battery to produce specific shapes of cathodes and anodes with current collector tabs. The size of the electrodes it cuts perfectly matches the standard pouches made by the cup forming machine, and the shape of the electrodes it produces is also handy for the latter processing steps of tab welding and electrode stacking.

Specifications:

| Power | 100 – 240V AC, 50/60Hz 100W |

| Maximum Punching size | 280 mm (L) x 180 mm (W) |

| Punching Accuracy | ± 0.1 mm |

| Die Cutting Stroke | 150mm |

| Air Cylinder | 3 Tons maximum Pressure |

| Feeding | Manually |

| Compressed Air | 0.5Mpa~0.8 Mpa |

| Vertical Burr | ≤15μm |

| horizontal Burr | ≤20μm |

| Long service life of the knife die |

Normal use ≥ 30,000 times |

| Equipment Weight | 180Kg |

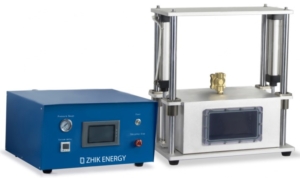

2] Pouch Cell Cup Forming Machine:

It is used for lithium polymer battery pouch cell cup forming in the production line of making pouch cell batteries.

Specifications:

Aluminium-plastic film with a maximum length of 300mm and a maximum width of 250mm (can be customised according to requirements).

Max. cup size: 160*190 mm. The depth of the punching shell is ≤6mm; the Pocket is not damaged, and the PP layer is not wrinkled.

| Supply Voltage | AC 220 V, 50 Hz |

| Power | 500 W |

| Compressed Air | 0.5 – 0.7 MPa |

| Al-laminated film thickness | 0.11 – 0.2 mm |

| Output Pressure | 5 T |

| Mold/Core Rough | 0.4 |

| Weight | 250 kg |

| Dimensions | 560 mm x 320 mm x 925 mm |

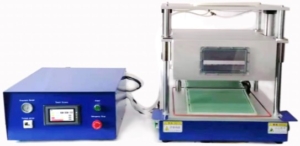

B] Ultrasonic Welding Machine for Electrode Pouch Cell

Description:

This is an ultrasonic metal welder designed for welding stacked electrode sheets (Copper & Aluminium) and tabs onto current collectors to prepare Li-Ion pouch cells in R&D laboratories. This welder is suitable for a maximum of 20 layers of electrode welding. The machine has a touch screen control panel for setting the parameters and/or welding programs, preset welding programs selectable for Al, Ni and Cu.

Specifications:

| Supply Voltage | AC 220 V, 50 Hz |

| Power Consumption | 0 – 800 W, adjustable |

| Welding Head | Two welding heads and two welding bases are included |

| Ultrasonic Frequency | 40 kHz, Auto tuned. |

| Dimensions (L x W x H) |

550 mm (L) x 300 mm (W) x 550 mm (H) (Controller) 480mm (L) x 240mm (W) x 385mm (H) (Welder) |

| Weight | 61 kg |

C] Stacking machine for Li-Ion Battery Pouch Cell Battery

Semi-automatic stacking machine:

Description:

It is a semi-automatic electrode stacking machine with advanced features to ensure a

stable, repeatable and precise electrode stacking. In its “Z” fashion stacking method,

Anode and Cathode electrodes are alternatively stacked with the separator film in

between. It is more precise and consistent.

1. Consistent tension controls for separator film delivery

2. “Z” fashion stacking with a separation via a foot-switch

3. Manual slidable fixtures enable accurate positioning and compactness of electrodes

4. Unreeling rotors for the separator film feeding, adjusting the fixture position

5. Can accept various sizes of electrodes

6. Automatic counting & zeroing for the number of stacks

Specifications:

| Working Voltage | 220 V AC 50 Hz, 200 W |

| Lamination |

Size – Min:L44*W44mm Max:L200*W150mm Thickness – 12mm Uniformity – ±0.5mm |

| Coil diameter of the diaphragm | Max:220mm |

| Air Pressure | 0.4-0.6Mpa |

| Dimensions | L510*W825*H585mm |

| Weight | 80 Kg |

D] 3 in 1 Vacuum Sealing Machine

Sealing machine for Li-Ion Pouch Cell:

Function:

The vacuum diffusion and pre-sealing all-in-one machine mainly removes air from the electrolyte under vacuum conditions after the electrolyte is injected into the polymerised lithium-ion battery/cylindrical battery, and finally forms a seal.

This device mainly has three functions: top-side packaging, pre-packaging, and vacuum sealing

for soft-packed lithium batteries. It consists of heating seals, vacuum air boxes and pneumatic heat

sealing components, which automatically complete the top-side packaging, pre-packaging and vacuum

sealing of battery aluminium-plastic casings.

Specifications:

| Compressed Air | 0.5 – 0.8 MPa |

| Power Supply | 220 V AC, 50 Hz Single phase |

| Power | 500 W |

| Sealing Head Temperature | Room – 2500C Adjustable, Accuracy ±2oC |

| Sealing Head Length | 200 mm |

| Product | 100 – 350 EA/H |

| Sealing Width | 5 mm, Customisable |

| Suitable battery Size | 180 x 120 x 10 |

E] Electrolyte Filling Machine

Description:

The bottle mouth divider is suitable for general acid and base, and low concentration of

strong acid and strong base, and salts.

• It has strong chemical tolerance.

• It can be disinfected and sterilised at high temperatures

• 4 models meet and cover the 0.5- 50ml capacity range.

• Convenient design ensures simple and economical cleaning and maintenance of the

splitter.

• Made of PTFE, FEP, BSG, PP and other materials

• Maximum pressure resistance 500mbar, maximum viscosity resistance 500mm2/s,

maximum liquid resistance temperature of 40°C, maximum liquid resistance density of

2.2g/cm3

Specifications:

| Specification ml | 0.5 – 5 / 1.0 – 10.0 / 2.5 – 25.0 / 5.0 – 50.0 |

| Minimum fringe ml | 0.1 / 0.2 / 0.5 / 1.0 |

| A ≤ ± | 0.5% 25 ul / 0.5% 50 ul / 0.5% 125 ul / 0.5% 250 ul |

| CV ≤ | 0.2% ul / 0.2% 10 ul / 0.2% 25ul / 0.2% 50 ul |

F] Electrolyte Diffusion & Degassing Chamber for Pouch cell Li-Ion Battery

Description:

Electrolyte diffusion & degassing chamber is specifically designed for Li-ion Battery Research. It is mainly used for removing air from the electrolyte after it’s been injected into the Li-ion cell or after the formation for final sealing under a vacuumed condition. It is easy to operate and suitable for all types of batteries.

Specifications:

| Power Supply | AC 240 V, 50 Hz Single Phase |

| Maximum Power | 50 W |

| Compressed Air | ≥0.6Mpa, ≦1.5Mpa |

| Chamber Body | 12 mm thick Aluminum case with observation window |

| Gas Filling Rate | ≦ 5 psi |

| Air Pressure Range | 0 – 1 Mpa (0 – 99 psi) Adjustable(Air Compressor is required) |

| Vacuum Level | – 0 .9 – 0 kPa Adjustable |

| Air Inflation Time | 0 – 99.99 sec |

| Vacuum Condition Hold time | 0 – 99.99 sec |

| Operation Temperature | -20 – 40 0C |