|

Cylinder Cell Equipment

|

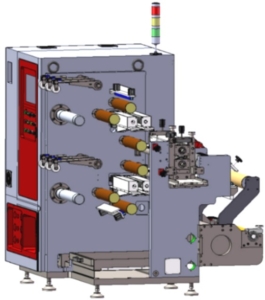

A] Slitting Machine for Cylinder Cell Li-ion Battery

Description:

A Roll to Roll Continuous Slitting Machine focusing on the design and

construction of the lithium battery industry, the equipment is mainly used for the post

rolling process, dividing the rolled pole pieces into multiple small rolls according to the

customer’s process, with a minimum cutting width of ≥ 10mm. This equipment is driven

and controlled by a servo motor and equipped with a precision planetary reducer, with

good stability, fast cutting speed, and high precision. The tool holder is compatible with

100mm blade cutters and fixed roller cutters.

Equipment structure: The main components of slitting include the unwinding mechanism,

correction mechanism, belt receiving platform, traction mechanism, slitting mechanism,

roller brush dust removal mechanism, pressing mechanism, pressing wheel mechanism,

and winding mechanism.

Specifications:

Roll diameter for unwinding : Max Φ450 ㎜

Unwinding weight Max : 200kg

Inner diameter of unwinding drum : Φ3” (Φ76.2mm)

Width of foil material : Max.300mm

Thickness of foil material : Copper foil: 6-20 μm; Aluminium foil: 8-25 μm

Splitting electrode sheet thickness : 90 ~ 250 μm

Roll diameter for winding : Max Φ450 mm

Inner diameter of Winding drum : Φ 3 “(inner diameter) (The drum is provided by the user)

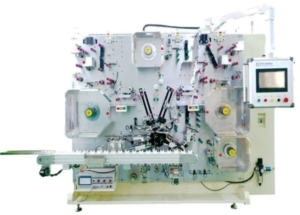

B] Automatic Winding Machine

Winding Machine for Electrodes of Cylinder Cell:

Description:

This device winds the positive and negative electrode plates and separators of the lithium-ion battery

components through mechanisms such as dust removal, tension control, quality inspection, length

measurement, travel correction, and static electricity elimination before winding the battery cells. After the core is made, it is reamed, hot punched, Short-circuit tested, and discharged from the conveyor belt. This device is suitable for batteries of model 32140etc.

Specifications:

Cathode electrode : 100-170mm (W), 80-300um (Thickness), 1000-3000mm (L), φ450mm (OD) & φ76.2mm (ID)

Anode electrode : 100-170mm (W), 80-300um (Thickness), 1000-3000mm (L), φ450mm (OD) & φ76.2mm (ID)

Diaphragm : 100-170mm (W), 15-40um (Thickness), φ300mm (OD) & φ76.2mm (ID)

Tape : 90-130mm (W), 20-50um (Thickness), φ150mm (OD) & φ76.2mm (ID)

| Diameter of winding needle | φ3.0mm/φ3.5mm/φ4.0mm/φ4.5mm/φ5.0mm ~ 10mm |

| Winding Diameter | Ø28-Ø38mm |

| Cell height | 110-180mm |

| Equipment Capacity | 12 ~ 15 PPM |

| Power | AC 220V 50HZ, 15KW |

| Dimensions | L3000 mm×W1500mm×H1800mm |

| Equipment weight | 3000kg |

C] Welding Machine

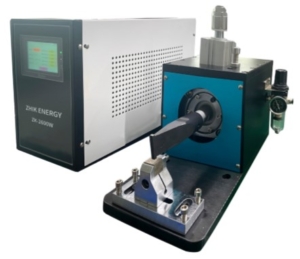

1] Ultrasonic Metal Welding machine

Description:

In Li-ion battery Ultrasonic spot welder with a touch-screen controller is designed for welding stacked electrode sheets (Copper & Aluminium) and Al & Ni tabs.

Features:

- Easy to operate

- Self-adjustable frequency

- Touch-screen control

Specification:

| Power Supply | Voltage 20VAC±10%, frequency 50Hz/60Hz |

| Welding Power | 0~2600W adjustable |

| Air Pressure Range | 0.5 ~ 0.8 Mpa |

| Frequency | 25 kHz |

| Welding layers | Continuous use of 1~30 layers |

| Solder size | Standard square 4×1.5mm, can be customised according to customer requirements |

| Control Way | HMI |

| Working Stroke | 15 mm |

| Welding time | 0.01~1s adjustable |

| Welding surface life | ≥ 150,000 times |

2] Single Point Pneumatic Welding Machine

Description:

The intermediate frequency inverter spot welding machine has superior performance and is

suitable for welding high thermal conductivity metal thin parts and fine workpieces.

Features:

1. Adopting a high-current inverter DC spot welding power source, the welding

performance is stable.

2. It adopts a split design, with adjustable welding head height and position.

3. Split structure, suitable for Electric vehicle battery battery pack, automobile battery

module, balance car battery pack, Kick scooter battery pack, mobile power supply,

starting battery pack module, electric tool battery pack, notebook battery pack, etc.

Specifications:

| Power Supply | 3 Phase AC 380V{220v} ± 10% 50/60Hz |

| Maximum Power | Approximately 6KW |

| Air pressure Range | 0.2 ~ 0.7 Mpa |

| Output Current | 5000 A |

| Welding Thickness | Maximum welding thickness :0.45mm |

| Machine Weight | About 30 Kg |

| Size for Machine (W x H x D) | 270mm × 330mm × 465mm |

D] Grooving Machine

1] Grooving Machine for Cylindrical Cell

Description:

1. Automatic feeding and unloading, high efficiency, time-saving and labor-saving.

2. The rolling groove size is adjustable, with high accuracy and stable size.

3. Replacing the mold can process various cylindrical battery rolling grooves, such as

18650.26650.21700

4. The machine has a small size, exquisite and beautiful appearance, and is easy to

operate,

5. Adopting PLC and touch interface operation, it is convenient to set various parameters.

Specifications:

| Power Supply | 220V 50HZ 0.2KW |

| Maximum Power Consumption | 200 W |

| Mould | Standard 18650 series mold, optional with other models |

| Rolling groove depth | 1.2 ~ 1.3mm(Adjustable) |

| Rolling groove width | 1.1 ~ 1.5mm(Customizable) |

| Processing accuracy | +/- 0.1mm |

| Life of hob | 3 million times |

| Product Dimensions (L x W x H) | 550 mm x 600 mm x 720 mm |

| Weight | About 50 kg |

E] Crimping Machine

1] PNEUMATIC CRIMPING MACHINE for Cylinder Cell

Description:

It is mainly used in the production of samples for the research and development of batteries

materials in the laboratory, the scientific research and the sealing of cylindrical batteries and

cylindrical capacitors, and can also be used for small batch trial production in factories. Other cylindrical battery sealing moulds are optional. The diameter 360 transition compartment of the glove box can pass directly from the transition compartment if there are no obstacles (slides), with a small size and convenient operation, stable operation and stable sealing. A built-in pressure gauge can observe and accurately control the sealing pressure.

The mould adopts a two-in-one design, and the sealing and shaping tool can be quickly switched

through the handle.

- One set of 18650 national pillar battery sealing mould is equipped as standard, which is sealed in two times (other round battery sealing moulds are optional).

- Air source: 0.4MPa hydrogen and nitrogen cylinder, or compressed air (compressed air is not recommended in the glove box.

- Exhaust design: specially designed exhaust port, which can be connected externally through

KF40 and other devices. - Gas consumption: about 0.5 L for single sealing

- Sealing pressure: controlled by regulating valve, recommended pressure 0.4MPa

- Sealing stroke: 30mm

- Sealing mould: 18650 series packaging mould is standard, and other specifications such as 212632

can be selected or added. - Installation dimension: L360mm * W220mm * H490mm

- Weight: about 30 kg

- It has the function of preventing a short circuit of the battery seal.

Features:

- Small size and light weight

- Simple operation

- Safety operation

Specifications:

| Driving Force | Manual hydraulic pressing up to 5T |

| Pressure Gauge | 0 – 3500 psi (0 – 250 kg/cm2 |

| Body | Stainless Steel |

| Dimensions | 228 mm x 176 mm x 360 mm |

| Weight | 26 kg |