List of equipment for electrode material synthesis

This co-precipitation reactor consists of a solution buffer (feed) tank, a synthesis reactor, and an aging reactor.

Solvent buffer (feed) tank x 3

5L 316 material + quick opening structure + PFA coating

Main reaction Kettle:

· Effective volume: 5L

· Material: SS316L (PFA coating is optional)

· Thickness of kettle body: 3mm

· Baffles: 4 pieces (left and right baffle width)

Adjustable degree

Design temperature: 0-95°C.

· Circulating water constant temperature: 0-95 °C.

Sealing form: dedicated sealing

· Jacket design pressure: micro positive pressure

4 inlet ports and 1 outlet port

1 overflow port, pH measurement

1 port, 1 nitrogen protection port,

1 temperature measurement port, reserved port 1

· Branch, double layer, 4-leaf, 45 ° diagonal (upper

Adjustable lower height

Aging Kettle:

· Effective volume: 5L

· Material: SS316L (PFA coating is optional)

· Thickness of kettle body: 3mm

· Baffles: 4 pieces (left and right baffle width)

Adjustable degree

Design temperature: 0-95°C

· Circulating water constant temperature: 0-95°C

Sealing form: dedicated sealing

· Jacket design pressure: micro positive pressure

One feeding port and pipe are included to feed the slurry from reactor kettle with one auxiliary port.

· Branch, double layer, 4-leaf, 45° diagonal (upper

Adjustable lower height

Specifications:

Mixing system:

· Mixing speed: 0~1000rpm variable frequency speed regulation

· Seal assembly: A special mechanical seal is adopted for the reaction kettle. The reaction kettle

can be protected by gas, and water circulation cooling is set to prevent this.

Failure of mixing seal due to overheating

· Agitator paddle:

Upper layer – adopt four-blade turbine type agitator, press down at 45°, and round the side.

Lower layer – adopt four-blade turbine agitator, turn up at 45°, and round the side

Kettle cover:

· Feed inlet and feed pipe:

The four feeding ports include: salt solution, alkali solution, ammonia water, and standby ports.

The feed pipe height can be adjusted, and one of the following two schemes can be adopted:

The protective tube is inserted from the top of the kettle.

The inner part of the top of the kettle is welded with inner wire, and one end of the protective

tube has outer wire, detachable

· Air inlet and outlet: One DN15 each

· Return port: DN15, inner wire is welded inside the kettle top, and the return pipe is connected

to the inner wire with outer wire

One temperature measuring port and one pressure port

Kettle body:

· Inner barrel: Mirror polishing of inner wall without welding slag

· Baffle:

The baffle width is adjustable and removable.

Corner rounding

· Jacket: Hot water circulation, external mirror polishing.

· Settling notch: DN25, inclined upwards, matched with DN25 to DN20 and DN25 to DN15 reducer.

· Overflow pipe:

Configure 2 overflow pipes0

Overflow pipe 1: DN15, directly opened at the side of the kettle top, with a downward inclination of 5°.

Overflow pipe 2: DN15, the outer side of the kettle inclines downward by 5°, the threaded overflow

pipe penetrates into the inside of the kettle, and the penetration position is tentatively determined as.

The middle of the kettle.

· Discharge pipe: DN20

· Sampling tube: DN15

Water circulation heating system:

· Hot water tank: SUS304, quick-opening union is adopted for pipeline

· Removable thermocouple and heating tube,

· Pipe: medical grade stainless steel

· The hot water circulating pump adopts German Weile hot water pump

Control system:

Temperature control system:

· Temperature control accuracy in the reactor: ± 1 °C.

· The temperature control range is RT – 90 °C.

· Adopt hot water circulation control mode.

· There are two ways to control temperature:

A. Circulating pump control: Set the temperature of the hot water tank separately and control the start

and stop of the hot water circulating pump according to the temperature setting value of the reactor.

B. Water tank temperature control: According to the temperature setting value of the reaction kettle,

the underwater heating element is controlled, and the hot water circulating pump is always on.

· Mixing motor control system: The mixing motor can rotate in both positive and negative directions,

and the rotation direction can be set clockwise and counterclockwise

· PH control system:

The detection accuracy of pH value reaches 0.01.

PH control accuracy is ± 0.1.

During pH control, the upper and lower limit of alkali pump flow can be set.

PID control mode shall be adopted for pH control.

· Feed system control:

In the manual mode, the start and stop of salt solution, alkali solution, ammonia solution and

auxiliary solution pumps can be manually controlled.

In the automatic mode, the start/stop and flow rate of feed pumps for salt solution, ammonia

solution and auxiliary solution can be set manually.

PLC Automatically control the flow rate of alkali feed pump.

The flow of each feed pump can be set.

With pump flow calibration function: the actual value of flow can be set on the HIMI panel.

After setting, according to the pump. The actual flow rate of the pump is displayed, and the

data collection of the pump flow rate is informed according to the actual volume.

Due to the different maximum flow of different types of pumps, the same peristaltic pump

with different types of feed pipe also causes the maximum flow.

Different, the maximum flow of the pump can be set on the HIMI panel, corresponding to

the maximum output signal, and can be used according to different.

Large flow, automatically adjust the flow accordingly.

Each feed pump can calculate the cumulative flow in ml; Cumulative feeding time, unit: min.

Each feed pump can be set with a timing start/stop function: specific time can be set, unit: min,

and then press the start key.

The pump feeding can be started automatically, and the time is counted down in minutes and

seconds. When the time reaches zero, the pump feeding will be stopped.

Specification

· List of components: Stainless steel (SS) funnel, glass flask, and SS rack.

· Funnel Material: SS304 Stainless Steel for durability and corrosion resistance.

· Flask capacity: 10L

· Vacuum Valve: Flask with a vacuum valve (pump included).

· User-Friendly Design: Flask designed for easy removal and handling.

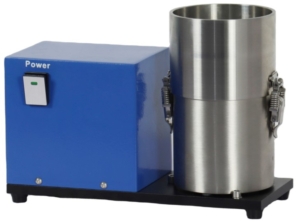

The Spray Dryer is mainly suitable for producing trace particle powders in universities, research institutes, and laboratories. It has broad-spectrum applicability to all solutions such as emulsions and suspensions, and is suitable for drying thermosensitive substances such as biological products, biopesticides, enzyme preparations, etc. The sprayed materials are only subjected to high temperature when sprayed into mist sized particles, so they are only subjected to instantaneous heating, which can maintain their active ingredients from being damaged even after drying.

Features:

1. Adopting a large color touch screen operation, combining fully automatic control and manual control, ten stage program temperature control, with built-in memory function.

2. Full automatic control: one button startup, after setting spray process parameters, the temperature reaches the preset temperature, the peristaltic pump starts automatically, the touch screen displays the running animation, and the running process is clearly displayed.

3. Manual control: If it is necessary to adjust the process parameters during the experiment, it is convenient to switch to manual mode, and the entire experiment process is dynamically displayed on the color touch screen (animation).

4. Shutdown protection function: When shutting down, simply press the stop button, and the machine will immediately stop running except for the fan. The equipment will not be burned out due to accidental operation (forcibly turning off the fan).

5. The machine has a misoperation protection function. When the fan and heater switches are used in the wrong order, the machine will automatically remind to prevent beginners from accidentally damaging the machine.

6. Equipped with a completely oil-free air compressor, the particle size of the powder is normally distributed, with good fluidity and low noise, which meets the national laboratory noise standards.

7. The atomization structure of two fluid spray, the whole machine is made of stainless steel materials, compact design, no auxiliary equipment, easy to use, as new as ever.

8. In order to meet the user’s requirements for adjusting various parameters within the experimental range, real-time PID constant temperature control technology is adopted in the design of drying temperature control, ensuring accurate temperature control in the entire temperature range and heating temperature control accuracy of ± 0.5°C.

9. To maintain the purity of the sample, an air inlet filter is equipped.

10. Time setting function: Users can set the working time of the machine by themselves, without the need for manual supervision. At the end of the working time, the machine stops working, without the need for manual supervision, greatly saving valuable time for customers to conduct experiments.

11. The whole machine is made of stainless steel, with two fluid spray atomization structure. The spray, drying and collection systems are made of transparent high borosilicate heat-resistant glass materials

12. The feeding amount can be adjusted by the feeding peristaltic pump, and the sample volume can reach 50ml. The sample stirring function is optional.

13. The dried finished dry powder has a relatively uniform particle size, with over 95% of the dry powder within the same particle size range.

14. By adjusting the atomization state, it is possible to collect powders with different particle sizes through different drying methods.

15. The small spray dryer is equipped with a nozzle cleaner (through needle) for viscous materials. When the nozzle is blocked, it will automatically clear, and the frequency of the needle can be automatically adjusted.

16. The automatic cleaning function of the drying tower eliminates the need for manual cleaning, greatly saving experimental time (optional).

Description:

This is a dual motion mixer requires small batch mixing for the early development of new products, and has high requirements for mixing uniformity. When researching new formulas in the laboratory, it is important to focus on mixed tasks. When the quantity is not large, a small mixing device is needed, and this product is a professional mixing device developed for this situation.

Features:

1. It can install various specifications of material barrels, adapt to various mixing tasks, and conduct small batch mixing experiments, fully tapping into the enormous potential of the equipment.

2. Adopting the patented technology of dual motion superimposed mixing, it has four major advantages of dual motion mixer: good, fast, versatile, and economical.

3. Easy to clean, the material barrel and blades of this model can be disassembled, making it easy to clean any part inside the material barrel and eliminating contamination between different batches of materials cross-contamination.

Product Description:

BS-UVS400X Ultrasonic vibrating screen machine suitable for checking the particle size

composition of ordinary abrasives, grading and particle size composition of superhard

materials.

Application field:

Widely used:Material research, Production, Laboratory testing in geological, Metallurgical,

Powder, Chemical, Construction, Cement, Pharmaceutical, Defense, and other departments.

Specification

(Model: BS-UVS400X)

Standard screening equipment 1-8-layer

Screening machine diameter 400mm

Screening particle size 0.038-3mm

Noise ≦ 50db

Feeding quantity (one-time) ≦ 250g

Amplitude ≤ 5mm

Voltage 220V

Speed 1420 r/m

Power 0.125KW

Overall dimensions of the host L560 x W500 x H536mm

Weight 35KG

Ultrasonic generator

Power supply AC 220V ± 10% 50~60Hz

Whole machine current ≤ 1A

High frequency current ≤ 0.8A

Operating frequency

38KHz High frequency ultrasonic generator. Equipped with a built-in microcomputer chip, it can

automatically track the digital frequency throughout the entire process according to the different states

of ultrasonic waves, without the need for manual adjustment, and the operation is simple and convenient.

Mode 4 consecutive modes, 1 pulse mode.

Maximum ambient temperature 45 degrees.

Wiring method Plug type, easy to plug in, convenient for replacement

Ultrasonic generator

High frequency connection line Cable connection is used between the ultrasonic oscillator and the

ultrasonic controller.

Connectors Aviation connectors.

Converter High frequency ultrasonic conversion device.

Ultrasonic grid Composed of an outer grid and a resonant ring.

Sieve Suitable for 10 mesh~635 mesh.

Product Description:

This is a muffle furnace mainly developed for the daily application of laboratories. High quality

furnace materials and stable temperature control systems can ensure the reliability of experimental data.

The product uses a new ceramic fiber material as the furnace material, high quality high-temperature alloy

heating element as the heating element, and the temperature controller uses an intelligent PID control module

to achieve accurate temperature control and constant temperature requirements

Specification

(Model: BS-MF3-12)

Product Features

The furnace is made of vacuum formed alumina ceramic fiber material, which does not drop powder at high

temperature and has small heat capacity · The heating element is made of high-temperature alloy wire, which

can bear large load, is stable and has a long service life · The heating speed is fast. It usually takes 15-30 minutes

to rise from room temperature to 1000°C · High temperature control accuracy, small impact temperature, temperature

compensation and temperature correction functions, accuracy of ±1°C · Intelligent PID temperature control instrument

is adopted, with program function, temperature rise curve can be set, and 30 program segments can be programmed

integrated structure, which can reduce the use of space, excellent appearance design, beautiful and generous · All electronic

components are Delixi products with leakage protection function · The machine will send out alarm signals for overheating

in the working process and automatically complete the protection action · After the instrument program is set, the next work

will be completed automatically as long as the run button is pressed · Air inlet can be optionally installed to purge and protect

inert gas such as air; Exhaust chimney can also be installed and connected with stainless steel corrugated pipe to discharge

toxic and harmful gases volatilized at high temperature in the furnace to the designated location.

Specifications:

· Furnace size: 150mm x 150mm x 150mm

· Maximum temperature: 1200°C

· Working temperature: 1150°C

· Temperature stability: ±1°C

· Heating rate: 1-20°C/min, freely adjusted according to the process

· Power supply: 220VAC±10% single phase, 50/60Hz

· Power consumption: 2.5kW

· Temperature control system: PID temperature control instrument, PID parameter self-adification function,

manual/automatic non-interference switching function, over-temperature alarm function, automatic heating,

automatic insulation, automatic stop, programmable for 30 periods, can meet the requirements of continuous

constant temperature and temperature control

· Heating element: Silicon carbide rod

· Temperature measuring element: N-type thermocouple

· Furnace materials: Polycrystalline alumina ceramic fiber material

· Security protection: Modular control will send out an acousto-optic alarm signal for overtemperature and interruption

during the work process, and automatically complete the protection action; install an empty circuit breaker on the device,

in case of short-circuit leakage, it will automatically pop up, which can protect the safety of the equipment and operators.

· Dimensions: 430mm × 465mm × 620mm

· Weight: 50Kg

This is a muffle furnace adopts a high-quality resistance wire as the heating element. It adopts a double-layer shell structure and a 50-stage program temperature control system. The furnace is phase-shift triggered and silicon-controlled. The furnace is equipped with an alumina multi-crystalline fiber material. The double-layer furnace shell is equipped with an air-cooled system, which can quickly raise the temperature. It adopts the overall welding seal of the furnace door and the furnace cover plate with a silicone O-ring seal. There is a cooling water-cooled O-ring at the furnace door. After passing through the flowmeter, the gas enters the back chamber, and exits, which can be uniform and there are multiple air intakes, which can ensure uniform and no dead angles. There are two air outlets at the furnace door of the furnace.

Specifications:

1. Furnace size: 300mm x 250mm x 250mm

2. Maximum temperature: 1600°C

3. Working temperature: 1550°C

4. Temperature stability: ±1°C

5. Heating rate: 1-20°C/min, freely adjusted according to the process

6. Power supply: 380-440VAC three phase, 50/60Hz

7. Power consumption: 9kW

8. Temperature control system: (i) 50 segment program temperature control intelligent PID adjustment.

(ii) The heating circuit of the electric furnace is automatically cut off when the temperature of the

electric furnace exceeds 1620 degrees or the thermocouple is burned out. The AC relay on the

main circuit will automatically disconnect, the main circuit will disconnect, the ON light on the

panel will turn off, and the OFF light will turn on, providing limited protection for the electric furnace.

(iii) Equipped with 485 communication interface (standard when purchasing software)

(iv) It has a power-off protection function, which means that when the furnace is powered on again

after a power outage, the program does not start to rise from the starting temperature but starts

to rise from the furnace temperature when the power is cut off.

(v) The instrument has the function of temperature self-tuning

9. Heating element: Silicon molybdenum rod

10. Temperature measuring element: B-type thermocouple

11. Furnace materials: Polycrystalline alumina ceramic fiber material

12. Security protection: The furnace door is equipped with a travel switch. When the door is opened, the

power supply will be automatically cut off to prevent electric shock hazards caused by touching heating elements.

13. Dimensions: 700mm x 840mm x 1160mm

Different Type: Planetary, Omni-Directional Planetary, Vibratory, Jet Mill, and Dual or 3D Movement Mixers

These are ideal for mixing dry powders to reduce the particular sizes.

Options: Low temperature, Vacuum Jacket

RPM Range: Up to 1000 RPM

Ball and Jar Material: Zirconia / SS / Tungsten Carbide / Nylon / Alumina / Agate

Planetary Ball Mill

Planetary Ball Mill

This is an omnidirectional planetary ball mill used as a preparation device for mixing, fine grinding, sample preparation, nanometer material dispersion, new product development and small batch production of high-tech materials. This product is small in size, full in function, high in efficiency and low in noise. It is an ideal equipment for scientific research institutions, universities, and industry laboratories to obtain microparticle research samples (four samples can be obtained at the same time for each experiment). It is equipped with a vacuum ball milling tank and can grind samples under vacuum. It has lock clamps for safety.

The omnidirectional planetary ball mill is suitable for wet and dry crushing and refining of hard, medium hardness, brittle and fibrous materials. The sample fineness can be less than 100 nm. It can also be used for grinding solids in suspension, sample mixing and homogenization, and metal alloying, which can achieve ideal and outstanding results.

Planetary Ball Mill: Theoretical Background

1. Under the influence of the geometric structure of the grinding medium and the special motion mode of high-frequency and high-intensity collision, shear and friction are generated directly by the grinding medium. During this process, the sample achieves an extremely excellent grinding effect-, with the characteristics of fast processing speed, small, uniform.

2. The material as a whole is far away from the revolution center in a group way. After rotating to a certain angle with the cylinder, it slides in the opposite direction of rotation. The grinding body pushes the powder layer away from the mill and exerts compression, shear and friction on the material.

3. After the material is turned to a certain angle with the grinding cylinder, the pressure on the cylinder wall is equal to zero, and the material is thrown off the cylinder wall, exerting an impact on the material.

4. The material rises along the concentric circle track and falls layer by layer in a circular flow state. It exerts extrusion grinding and friction on the powder.

5. The material moves in a circle with the grinding ball and slides relative to it, exerting friction on the powder.

The material at the cylinder wall does not slide and rotate with the grinding cylinder, thus losing the crushing effect, but it can be used to protect the inner wall of the grinding cylinder and reduce wear. The circulation and sliding motion play a major role in fine crushing.

6. Main plate rotation: When the planetary tank body is working, the planetary main plate will rotate continuously 360 degrees or work at any angle, so that the material can fully participate in the grinding. This type is also known as the non-dead angle planetary grinder.

6. Main plate rotation: When the planetary tank body is working, the planetary main plate will rotate continuously 360 degrees or work at any angle, so that the material can fully participate in the grinding. This type is also known as the non-dead angle planetary grinder.

7. The G-Force Calculator: To convert revolutions per minute (RPM) to relative centrifugal force (RCF), or g force, use the following formula: RCF = (RPM)2 × 1.118 × 10-5 × r. Relative centrifugal force is dependent on the speed of rotation in RPM and the distance of the particles from the center of rotation.

The Force exerted on a sample in a centrifuge is a function of the rotation speed of the centrifuge (RPM) and the radius of the rotor.

Formula :

RCF or G-Force = 0.00001118 x Rotor Radius (cm) x (RPM)²

RCF or G-Force = 0.0000284 x Rotor Radius (inch) x (RPM)²

Planetary Ball Mill

Model: BS-PBM2LY

· Electrical Description: 200-240V AC, 50-60Hz, 0.75 kW

· Feed Material: Soft, Hard, Brittle, Fibrous-dry or wet, Hard Abrasive, Hard Brittle, Medium Hard

· Material Feed Size: Brittle materials are less than 10mm, others are less than 3mm

· Final Fineness: <100 nm

· Grinding method: Dry/wet/high-energy alloying grinding/vacuum grinding

· 360° speed (variable frequency adjustable): 1-14/min

· Speed ratio (revolution:rotation): 1:2

· Planetary speed (variable frequency adjustable): Maximum revolution 0-400r/min, rotation 0-800r/min

· Total planetary speed: 1200r/min

· Speed control mode: PLC variable frequency control system and touch screen control system.

· Transmission mode: Gear drive

· Batch Size / Feed Quantity: 4 x 500 ml.

· Grinding Jar Volume Acceptability: 50 ml ~ 500 ml

· Vacuum Jar Volume Acceptability: 50ml ~ 250mL

· Operation mode: Two or four tanks work at the same time

· Maximum continuous working time: 72 hours (timer 0-9999h)

· Program control: The ball mill is controlled by high-tech micro-computer chip, and it can run forward and reverse repeatedly (0-999min) and forward, pause, reverse, pause and forward (0-999min) alternately according to the setting procedure, especially suitable for the need for cooling or intermittent operation.

· External dimension: 950mm x 550mm x 650mm

· Weight: 96Kg

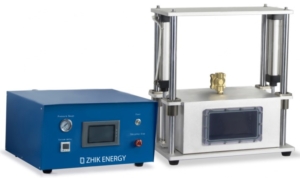

Vacuum Mixture with Vacuum Pump

Product Description

The Vacuum Mixture is designed to produce a coating slurry by mixing small

batches of chemicals and compounds under a vacuum to remove gas bubbles and

protect the sample from oxidation. It has a built-in pump can vacuum the mixing

container and the step-less mixing speed varies from 0 to 320 rpm. The vibration

plate is located at the bottom to remove gas bubbles before vacuum

mixing and disperse the slurry after mixing to ensure better uniformity.

It is excellent for preparing battery electrode paste and various ceramic materials in research labs.

High filtration precision, up to 124 microns, equipped with positive and negative particle filters.

All SUS304 stainless steel designs have good anti-corrosion performance and are easy to clean.

The filter screen with a large filter area makes the pressure loss very low and the equipment is durable.

Small size, easy to operate. A steel cup is there to measure slurry.

Beautiful appearance, easy maintenance, molding and other advantages

Specification (Model: BS-VM7)

Power supply: 220-240 VAC single phase, 50Hz

Power: 150 W

Capacity: 1000 mL

Default filter: Filter 80, 100, 150 mesh

Rotary Speed: 320 rpm

Slurry Viscosity: Max. 10000 mPa·s

Vacuum pump: Built-in single-stage vacuum pump

Vacuum Level: -0.08 ~ 0.09 Mpa

Mixing time: 0~99 Minutes Adjustable

Vibration Plate: Vibrating at 1000 Hz

Pump Flow Rate: 3 L / min

Dimensions: L400mm x W380mm x H620mm

Weight: 35Kg

Filtration System for Battery Electrolyte Slurry

Description

- High filtration precision, up to 124 microns, equipped with positive and negative particle filters.

- All SUS304 stainless steel designs have good anti-corrosion performance and are easy to clean.

- The filter screen with a large filter area makes the pressure loss very low and the equipment is durable.

- Small size, easy to operate. A steel cup is there for measuring slurry.

- Beautiful appearance, easy maintenance, molding and other advantages

Specification (BS-GL10)

Power Supply: 220V AC (Single Phase), 50Hz

Pump Flow Rate: 3 L / min

Absolute Vacuum Level: 65 kPa

Capacity: 1000 mL

Default filter: Filter 80, 100, 150 mesh

Filter Container Dimensions: minimum 140 mm × 70 mm ×150 mm

Air Generator Dimensions: minimum 150 mm × 150 mm × 200 mm

Space requirement: 20cm × 20cm

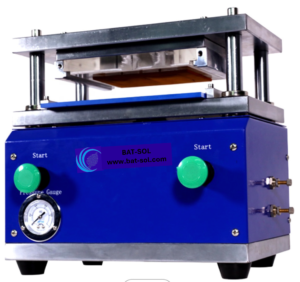

Product Details

An automatic film coater is a Large Automatic Film Coater designed to produce films with consistent thickness by using micrometre adjustable applicators or fixed thickness applicators. It has a unique driving system to produce a smooth coating on all types of materials. One micrometre adjustable applicator is included for immediate use.

Specification:

| ITEM | Data |

| Working Voltage | 220V , 50Hz |

| Feed speed | 0 ~ 100mm/s, the speed can be adjusted |

| Max.Stroke Length | 10 – 250mm adjustable (According to customer request) |

| Vacuum plate | With vacuum aluminum plate |

| Scraper range | 0.01~3.5mm adjustable |

| Vacuum Pump | Yes |

| Product Dimensions | L500mm×W310mm×H200mm |

| Platform Dimensions | L365mm×W200mm×H30mm |

| Net Weight | 50 kg (135 lbs) |

| Warranty | One year warranty and lifetime maintenance |

2. conditions for all coating material

3. Aluminum alloy flat vacuum plate with built in vacuum pump and allow you put on or release substrate quickly

4. Built-i

n pushing bar for using micrometer adjustable applicator or frame film applicator

5. Adjustable position switch allow you set up a stroke from 10 – 250 mm

6. One 150 mm width micrometer adjustable film applicator is included (thickness adjustable from 0.01 – 3.5 mm)

7. Heating cover is built in with digital temperature controller for drying film within 200℃ within +/-1oC.

8. Vacuum pump is not included in the coater to avoid vibration. You can use your own vacuum pump or order optional vacuum pump from us.

9. 3/8 ” ID x 48″ L hose is included for connecting pump and coater.

Vacuum Oven with Digital Temperature Controller

Drescription

DZF series vacuum drying oven (vacuum oven) is specially designed for drying heat sensitive,

easily decomposed and easily oxidized substances, and can be filled with inert

gas, especially some complex items can also be quickly dried.

Features

- Cuboid Studio, make full use of effective volume, microcomputer temperature

controller, accurate and reliable PID precise temperature control built-in over-temperature protection. - The tempered, bulletproof double-layer glass door to observe the objects in the studio at a

glance. - The closing and tightness of the box door can be adjusted, and the integrally formed

silicone rubber door seal ensures a high degree of vacuum in the box. The fitting port is built-in for connecting a vacuum pump (optional) with Quick Clamp with Rubber O-Ring. - The vacuum oven comes with a Silicone gasket. A good vacuum sealing is achieved by the silicone gasket and the positive latch door.

- The double-layer observation window consists of >1/2″ tempered glass and a transparent polycarbonate shield.

- An adjustable leak valve for venting is included.

- There is a port on the back of the oven for connecting with the vacuum pump (optional).

- The studio is made of stainless steel plate to ensure the product is durable.

- Storage, heating, testing and drying are all carried out in an environment without oxygen or full of inert gas, so it will not oxidize

Specifications

Working Power : 100 – 240V AC, 50/60Hz

Power Consumtion : 1200 W

Working Temperature : RT – 250 °C

Capacity : 25 Liter

Temperature control accuracy : ±1°C

Temperature uniformity : ±5°C

Degree of vacuum : < 133Pa

The Inner Chamber size : 300 mm × 300 mm × 275 mm

The Product Dimensions : 590 mm × 490 mm × 450 mm

HOT ROLLING PRESS

Product Details (Model: BS-HRP100)

BS-HRP100 is a compact Hot Rolling Cylinder Press with max working temperature of

200°C, High torque DC motor is Ar gas compatible. It serves well in the application such as

increasing active material density of the electrode in Li-ion batteries research after coating.

It has a pair of 100mm width steel rollers with a maximum heating capacity of 200°C.

• Heating and rolling, the temperature controlled by the thermostat is adjustable and

displayed in numbers.

• Choose to work with or without heating.

• The roller has high hardness, and the surface is plated with hard chrome, the hardness

can reach HRC62 and rust-proof.

• Adopt the inclined block to adjust the tableting gap, which has good self-complexity

and high adjustment accuracy.

• High rolling precision, roller cylindricity≤±2um.

• Vertical design, convenient for feeding and rolling of sheet and strip materials.

• Adopt gear meshing rotation to realize roller pressing.

• The thickness and speed of the tablet can be adjusted, and the appearance is exquisite.

• Electric rolling, forming automation, can be forward and reverse operation.

• Small size, easy to operate, flexible and fast to use.

Description

BS-MQ180S is suitable for die-cutting and forming of battery positive and negative plates. The single-piece die-cutting of the plate-type pole piece is pneumatically used. The machine can be used inside a glove box with Ar atmosphere where moisture/oxygen–sensitive electrodes will be cut (such as lithium metal electrode for Lithium-Sulfur, Lithium Air, and Lithium Solid-State batteries).

Product Parameters

Product Name: Pneumatic pole piece die cutting machine

Die Set Dimensions:

- Two standard electrode (Cathode & Anode) cutting dies are included.

- Cathode Die: minimum 56mm (L) × 43mm (W). With 14mm (L) × 11mm (W) protrude current collector.

- Anode Die: minimum 58 mm (L) × 45 mm (W). With 13 mm (L) × 11 mm (W) protrude current collector.

- Cutting Thickness: Max. 0.5 mm

- Cutting Accuracy: ±0.1 mm

- Cutting Pressure Force: Max. 1 T

Feeding: Manually

Stroke Length: ≥ 12 mm Cutting

Die Life Span: Maximum 30000 strokes

Description

This is a handheld disc cutter used to cut the battery electrode. It includes a set of rings and cutting dies. The cutting diameter can be customized according to users’ requirements. For coin cell batteries, we often use 14mm, 15mm,16mm, 18mm, 19mm, and 20mm models.

Type: Handheld type

Cutting diameters: 8 – 20 mm, please choose the diameter while ordering

Cutting thickness: 0.2 mm Max. for soft metallic foil with coating

Cutting Accuracy: ± 0.01 mm

Pressure: 6 kN

Max. Stroke: 20mm

Die cutting burr height: ≤0.02mm

Size: 23cm x 12cm x 10cm

Weight: 1 Kg

Product Details

- The equipment used for the lithium-ion battery cutting electrode

- automatically, the user can set the size of the cut length. It’s mainly consists

- of the drive part, PLC control, and cutting device (or automatic discharge device)parts.

- The drive part adopts the motor driver of feed rollers to cut electrode;

- PLC controlled using a special motor drive can be realized English

- display, length setting, and speed setting; the cutting device adopts precision

- mold, the up and down knife mold and pneumatic driven, automatic feeding

- according to the electrode feeding, or according to the coating gap to track

- for electrode cutting,cutting can be set many time

s.

s. - 2.Technical parameters:

- 2.1. power:1KW

- 2.2 cut materials :anode and cathode electrode, or their clearance electrode

- 2.3. cutting range: 500mm

- 2.4. Cutting precision: ± 0.3mm

- 2.5. Speed: 0-12m/min adjustable

- 2.6. unwinding tension adjustment: 12Nm

- 2.7 Dimension:L*W*H=1450*1250*1050mm

- 3.Performance:

- 3.1. This equipment adopts step motor feed drive,high precision of

- fixed-length

- 3.2. PLC control,the english set the length,easy operation,intuitive;

- 3.3. digital set-length of cutting,cut the length of gap tracking;

- 3.4. pneumatic drive,low noise

Product Details

BS-CC20E It is a compact button battery packaging machine with adjustable packaging pressure, which can be used to package CR20

series of button batteries (CR2016, 2032 and 2025). This packaging machine uses a motor that can run in an Ar atmosphere. There is no hydraulic oil in the packaging machine, so compared to hydraulic packaging machines, this electric packaging machine is more suitable for operation in a glove box. The instrument is equipped with a PLC touch screen for easy adjustment of parameters. The sealing pressure can be adjusted according to requirements.

Specifications

Power supply: voltage single-phase 110V~220V AC±10%; frequency 50Hz/60Hz; power 100W

Sealing pressure: Max. 1000Kg, digital display can be set

Sealing stroke: 30mm

Sealing mold: Standard CR20 packaging mold (CR2016, CR2025, CR2032), optional other molds

Dimensions: L250mm XW185mm X H450mm

Weight: 25kg

Product Details

Compact Hydraulic Crimping Machine: One for All Button Cells of CR2016, CR2025, & CR2032 (Optional Die CR1220, CR2325 or CR2450, AG3, AG5) – GN-110

-

-

- It is a newly designed coin-cell crimper with lighter weight and a smaller footprint. The crimper is suitable for sealing various types of coin cells such as CR2032,CR2025,and CR2016 with included die. It can also crimp CR2325, CR2450, AG3, AG5 and other special size cases with optional die sets.

- In addition, customers can easily replace the original die for disassembling purpose.

- It is an ideal tool for operations in a glove box.

-

Specification

| Standard Crimping Die | One set of crimping dies for all CR20XX coin cell, such as CR2045, CR2032, CR2025 and CR2016, etc. |

| Structure | Heavy Duty Steel plate |

| Pressure | Max. 8 metric Tone hydraulic with automatic return |

| Net Weight | 25Kg |

| Machine overall Dimension | 300L x 190 W x 310H mm |

| Shipping Weight | 35 Kg |

Description:

This is an ultrasonic metal welder designed for welding stacked electrode sheets (Copper & Aluminum) and tab onto current collectors to prepare Li-Ion pouch cells in R&D laboratories. This welder is suitable for max. of 20 layers electrodes welding. The machine has a touch screen control panel for setting the parameters and / or welding programs, preset welding programs selectable for Al, Ni and Cu. The real-time welding current can be visible on the ampere meter display.

Specifications (Model: BS-800W):

✓ Input Voltage: 220V AC Single Phase, 50/60 Hz

✓ Max. Power Consumption: 0-800W, adjustable

✓ Welding Area: 3mm(L) x 3mm(W), can be customized according to customer’s requirement.

✓ Touch Panel Control

✓ Welding Head: Two welding heads and two welding bases are included–

➢ Welding Craft 1: Welding pure Al tab 0.1mm + pure Al foil 0.012-0.018mm within 20 layers

➢ Welding Craft 2: Welding pure Ni tab 0.1mm + pure Cu foil 0.012-0.018mm within 20 layers

✓ Ultrasonic Frequency: 40 kHz, Auto tuned.

✓ Welding time: 0.01 ~ 2 seconds.

✓ Working Mode: Pneumatic program control

✓ Working air pressure: 0.2 MPa – 0.7 MPa

✓ Machine Size:

➢ Controller: 550mm (L) x 300mm (W)x 550mm (H)

➢ Welder: 480mm (L) x 240mm (W) x 385mm (H)

✓ Weight: 61 Kg

Product Details

- Basic Function and Features:

It is mainly for square power LIB cell’s precisionly winding.

- SPECS

1)Winding needle group width:15-30mm;30-75mm

2)Separator width:80-130mm

3)Electrode width:78-128mm

4)Electrode length:300-1500mm

5)Ending tape width:10-15mm

6)Winding precision: the aligning error between separator and cathode,cathode and anode electrode all less than ±0.5 mm

Requests to materials:

- Electrode width error less than 0.1mm

- Electrode’s S curve error less than 0.5mm/1000mm,also without raise edge phenomenon

- Separator’s turriform error less than ±0.2mm, also without raise edge phenomenon

7)Machine capacity:3-6PPM(related to the length of the electrode and the artificial feeding speed)

8)Drum shell rate:cell thickness<5mm,drum shell rate <2%

Cell thickness>5mm,drum shell rate<3%

3.Supporting facility:

1)Space: 1500 mm(L)×1300mm(D)×1500mm(H)

2)Supply power: 220 VAC±5﹪,Single phase,1 KW

3)Air supply: 5~7 kgf/cm²,100 l/min

4)Non-corrosive gases,liquids,explosive gas

Automatic Digital Bottle Top Dispenser

Automatic Digital Bottle top Dispenser for Electrolyte filling (BS – LAB50)

Description:

This is an automatic digital bottle top dispenser for electrolyte filling. To protect light-sensitive media, the installed clear cylinder inspection windows can be easily replaced with the supplied clip-on, amber-coloured windows. Dispensing up to 50mL per batch for lithium-ion battery research. It can be quickly and easily disassembled for cleaning, to replace the piston/cylinder, or to replace the bottles. An innovative new measuring system that matches the Class A accuracy of glass burettes with 2 decimal place readings.

Features:

- It has strong chemical tolerance.

- It can be disinfected and sterilized at high temperature

- Convenient design ensures simple and economical cleaning and maintenance of the splitter.

- Made of PTFE, FEP, BSG, PP and other materials

- Maximum pressure resistance 500mbar, maximum viscosity resistance 500mm2/s, maximum liquid resistance temperature of 40°C, maximum liquid resistance density of 2.2g/cm3

Specifications:

- Dispensing volume: 50ml

- Minimum volume: 1ml

- Accuracy: ≤±0.5%, 250 µl

- CV: ≤0.2%, 50 µl

Pouch Cell Case / Cup Forming Machine

Description

Pouch case forming machine is used for lithium polymer battery pouch cell cup forming in the production line of making pouch cell batteries

Features

* Adopt four guide post structures, smooth up and down sliding and high precision;

*It is simple and fast to change the mold and adjust the drawing depth;

*Compared with similar products, the aluminum-plastic film of the same quality stretches

deeper and more stable.

*Precise mold design, no crow’s feet and slumps at all corners and surrounding areas of

the product after molding;

*It is protected by a light curtain and cover, which is safe to use;

*Mould materials imported from Japan and high-strength chrome steel and alloy aluminum

are used, and the surface is treated with environmentally friendly electroplating and baking

paint;

*Exquisite appearance, the sheet metal adopts a three-dimensional geometric design,

simple and beautiful;

* Easy to operate, safe and reliable, small size

Specifications

Power Consumption : 200 W (Max)

Cup dimension with single cup : Maximum 190mm (L) × 160mm (W) x 6 mm (H), can be customized.

The distance between Top and Bottom Die : 70-75 mm maximum

Cup Depth to Punch : 4-6.0 mm (Max)

Punching Pressure : 5 Metric tons

Stroke Frequency : < 8 seconds per trial

The thickness of Aluminum Laminated Film: 0.10 – 0.20 mm

Electrolyte Diffusion & Degassing Chamberr

Description

BS-VS300V electrolyte diffusion & degassing chamber is specifically designed for

professional Li-ion Battery Research. It is mainly used for removing air from the electrolyte

after it’s been injected into the polymer Li-ion cell or after the formation for final

sealing under a vacuumed condition. It is easy to operate and suitable for all types of

batteries(especially soft bag batteries and cylinder batteries). Unique periods of the vacuum

control system allow electrolytes to thoroughly saturate the electrodes to ensure the best

battery charging-discharging performance

Features

1. The vacuum box is sealed without air leakage, and a transparent plate is set at the front.

2. There is a safety light curtain on the front to prevent the wrong operation of the foot switch during operation.

3. The degree of vacuum can be set by a digital vacuum gauge.

4. The vacuum delay time and rest time can be preset;

5. Except for the front plexiglass plate, the rest of the box is an oxidized aluminum plate;

6. The front panel is centrally set, controlled by a foot switch, and has conversion buttons, manual buttons, time relays, and vacuum pressure gauges; easy to operate and set;

7. The whole machine runs safely and stably, with reliable control and convenient operation.

8. It is glove box compatable

9. Optional with observation window

Specifications

Power Supply : 220V AC (Single Phase), 50 Hz

Power Consumption : 500W

Inner Chamber Size : 320 mm (L) × 320 mm (W) × 175 mm (H)

Tray Dimmension : 220 – 250 mm (L) × 120 – 200 mm (W) × 80 -100 mm (H)

Chamber Body : 12 mm thick Aluminum case with the observation window

Gas Filling Rate : ≤ 5 psi

Air Inflation Time : 0 – 99.99 sec

Vacuum Condition Hold Time : 0 – 99.99 sec

Operation Temperature : -20 to 40 ℃

Product Image:

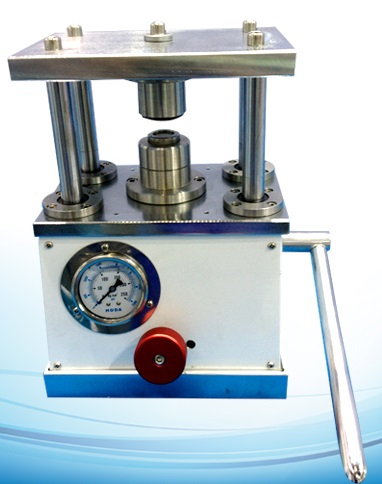

Description:

This is a cold isostatic press is a device that can press powder materials into sheets, which can

be widely used in silicate, ceramics, powder metallurgy, lithium batteries and other industries. The

equipment uses the motor as the hydraulic drive system and uses a digital pressure sensor to

accurately control the pressure force. It is ideal for research and development and small batch

trial production of powder filming equipment.

Specifications:

• Pressure range: 0 – 40T for 30mm ID vessel (38T for continuous use)

• Piston diameter: 130mm (d)

• Pressurized method: Manual pressurized

• Vessel Pressure: 0 – 500 MPa

• For calculating the actual pressure (MPa) applied to your working piece, please follow the

equations below:

P = T x g x 10 / (π x r2)

P: Actual pressure (Mpa) on the working piece

T: Actual force (metric ton) applied on the pressure vessel cylinder

g: gravitational acceleration of earth g ≈ 9.8 m/s2

π: ~3.14

r: Radius (cm) of the Pressure Vessel (1.5 or 2.5 cm)

• Maximum piston stroke: 50mm (T)

• Protective shield: Perspex

• CIP Vessel Size:

Inside: 30 mm (I.D.) x 110 mm (H)

Overall: Overall: Φ100 × 315 H (mm)

• Dimensions: 355mm x 215mm x 710mm (L x W x H)

• Weight: 130Kg

• Weight: 130Kg

• Compliance: CE Certified

• Diagram of cold isostatic press:

SEMI-AUTOMATIC ELECTRODE STACKING MACHINE (MODEL: BS-DP200S)

Description:

This is a desktop semi-automatic electrode stacking machine with advanced features to ensure a stable, repeatable and precise electrode stacking. In its “Z” fashion stacking method, Anode and Cathode electrodes are alternately stacked with the separator film in between.

Features:

- This is a Tabletop type machine has a small and compact footprint. It can be placed on the ordinary desktop.

- Z-shape semi-automatic stacking machine, separator automatic tension control.

- The machine has automatic lifting and placing of the electrodes in the stacking position function.

- Automatic counting of stacking number, manual zeroing, design digital display counter.

- The machine has PLC driven touch screen control for all the functions.

- Electrodes to be placed manually and the fixture is used to assist the positioning to ensure the uniformity of the stacking for different electrode dimensions.

- The machine has a button switch which is adopted to control the operation of the air cylinder and the PLC is driven.

- The machine has an in-built vacuum pump to pick up the electrodes automatically.

- Accommodate a wide variety of electrode dimensions, if needed.

Specifications:

- Alignment accuracy : < 0.5 mm

- Separator width : ≤105mm

- Maximum separator roll : φ200 mm

- Applicable electrode size : L 55 – 100 mm, W 40 – 105 mm, H 2 – 8 mm

- Tab length : ≤25 mm

- Swing roll travel : 180 mm

- Air pressure source : 0.5MPa ~ 0.7MPa

- Input Voltage : AC220V Single Phase, 50 Hz

- Machine Size : L710 mm × W600 mm × H770 mm

- Weight : 80 Kg

- Vacuum pump : In built vacuum pump

Coming Soon….